Maintaining constant success in the competitive fields of delivery and transportation depends on maintaining safety, dependability, and efficiency. One amazing development in this area is the inclusion of liftgate technology into fleet vehicles. Leading this revolutionary movement is TER Texas, proving how liftgate installations may give companies a major competitive edge.

Table of Contents

Simplifying Processual Effectiveness Liftgates provide a strong way to improve loading and unloading procedures across many sectors, particularly in transportation and logistics, where prompt service is critical. Using liftgate technology can help companies greatly lower the physical strain on their staff and enable faster and more effective freight handling. This reduction of physical strain not only lowers the possibility of staff injuries but also enables companies to maximize their delivery capacity, hence increasing the volume of shipments handled within approved time frames.

Liftgates also help to close the distance

Close the distance between loading docks and delivery vehicles, therefore facilitating a more flawless operational flow. Faster turnaround times and higher customer satisfaction follow from this increased efficiency since more consistent, timely delivery results. TER Texas is aware that implementing liftgate technology is not only a tactical improvement but also a strategic one meant to increase operational output and preserve a competitive advantage in a market getting more and more demanding. By giving the integration of liftgates priority, businesses may effectively respond to the changing needs of their customers and streamline logistics operations for the best efficiency.

Creating Strong Safety Guidelines

In all fields, but especially in logistics and delivery, where hand handling large objects increases the danger of accidents, safety is a first concern. By relieving employee physical strain and hence promoting a safer working environment, lift gates significantly help to reduce these risks. Safety is very important to us at TER Texas, hence, our liftgate design solutions must guarantee that thorough safety procedures are naturally part of our products.

Respecting Professionalism and Client Contentment

Giving a fleet of liftgates shows a great dedication to professionalism and makes a favorable impact on customers. Purchasing premium tools improves client impressions as well as loyalty and confidence. TER Texas claims that making wise commercial decisions by investing in better-fitting solutions, such as liftgate installations, helps to build enduring customer connections.

Seeing Long-Term Cost Effectiveness

Although the initial outlay for liftgate installations would seem significant, the long-term advantages are really large. Among these benefits are lower labor costs, less injury claims, and less damage to items handled. Liftgates are a sensible financial decision that can increase income over time by enhancing operational efficiency.

Customized Solutions for Specialized Corporate Needs

Here at TER Texas, we understand that every company has unique needs and obstacles. Our liftgate installation capabilities are tailored to fit every company’s particular requirements. Working closely with clients, our knowledgeable staff searches for the best liftgate solutions that fit their corporate goals.

Join forces with TER Texas.

Using Ter Texas’s creative vehicle upfitting ideas will help your fleet’s output, safety, and general reputation be much improved. Our main goals are to establish a surrounding marked by security, effectiveness, and a strong customer concentration.

Making forward-looking investments in liftgate technology can help your company to flourish and increase output. Get in touch with TER Texas right now to learn how we might help your company to reach amazing success. Allow us to work with you to see your company soar.

Liftgates have long been essential

In the fields of logistics, goods handling, and transportation, to help make cargo loading and unloading safer and quicker. By allowing large goods to be raised or lowered to ground level, these hydraulic or electric platforms attached to the rear of trucks help to minimize the demand for manual labor and stop mishaps. But contemporary liftgate technology has developed well beyond basic platforms. Recent developments have turned them into sophisticated tools that optimize operational productivity and not simply increase worker safety.

Knowing Liftgates: The Foundations

The technical development of liftgates is investigated in this paper, with particular attention to how these developments lower hazards, increase efficiency, and simplify processes in many different sectors.

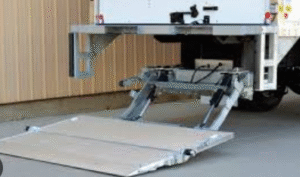

Installed at the rear of a truck, van, or trailer, a liftgate is a mechanical mechanism often run by a hydraulic or electric system. By lifting or lowering products between the ground and the cargo space of the vehicle, it primarily loads and unloads commodities.

Liftgates: Various Types

Tuck-Away Gates

Fold and keep under the car when not in use. Perfect for delivery vehicles making plenty of stops.

Raillift Gates

Mount to the rear frame with big platforms. Perfect for more substantial and bigger objects.

Cantilever Lifts

Provide a tilting system to equalize loads. Ideal for uneven surfaces.

Column lifts gates

Side Loaders: Liftgates

Often used for large machinery or palletized items, high-duty and vertical refer to vertical orientation. Open from the side rather than the rear. Ideal for limited areas of delivery.

Liftgate Technology’s Development The demand for more sophisticated liftgate systems has grown as delivery needs have grown, especially with the advent of e-commerce. Liftgate technology has developed thus:

Smart Control and Automation

Modern liftgates often include configurable settings and automated controls, including smart sensors. These gains allow:

- Platform precision placement.

- Remote control using wireless means.

- Load recognition changes either movement speed or load balance.

- Features allowing automatic stow and deployment help to lower operator error.

- These improvements drastically expedite cargo handling and reduce human mistakes.

Integration of Telematics

Liftgates today interact with fleet telemetry systems, enabling fleet managers to follow maintenance schedules, check usage trends, and get real-time alerts.

- Benefits include:

- Planned preventative maintenance helps to avoid downtime.

- Security and compliance with GPS-based use tracking.

- Monitoring wear and tear helps to extend the lifetime of equipment.

Mechanical Efficiency and Electric Power Units

- Old liftgates were hydraulic and needed

- continuous fluid monitoring. Modern advancements now provide:

- Less power-consuming hybrid hydraulic-electric versions.

- high-capacity lithium-ion cell battery-powered devices.

- Fast-charging capability, perfect for delivery cars making several stops.

Safety Improves

For businesses and employees equally, safety is their main priority. Advanced liftgate mechanisms comprise: Anti-slip platforms stop falls and slips. LED lighting for nighttime operations’ view-through needs.

sensors for obstacle detection that stop motion should something is in their path. Visual warnings and backup alarms help to stop crashes. These characteristics greatly lower the accident risk.

Lightweight, Long-lasting Materials Made of aluminum and composite materials, liftgates today help to lower the total weight of the vehicle while preserving strength. Rewards include:

Enhanced fuel economy.

Less strain on suspension systems. More payload capacity. Increasing Productivity with Liftgate Innovations

Quicker Load and Unload Faster lift cycles and remote controls let updated liftgates let operators load and unload goods in a fraction of the time it used to take. This especially helps:

Courier services with delivery timed for urgency. Food and grocery stores need temperature-regulated logistics. Deliveries of furniture and appliances, where big objects require delicate treatment.

Lowering of Labour Costs

Automation lessens the need for several people to load and unload. Now, one trained operator can perform the tasks of two or three, so saving labor costs and lowering injury claims.

Improved Dependability and Uptime Liftgates with clever diagnostics systems alert early on for maintenance problems. This guarantees long-term dependability and helps to avoid expensive breakdowns during active routes.

Industry Applications of Advanced Liftgates 1. E-commerce and Retail Giants depend on effective last-mile delivery. Even to sites without loading docks, automated lift gates with tracking guarantee packages are delivered safely and fast.

Pharmacy and Medical Treatment

Liftgates with soft-touch loading help delicate tools and temperature-sensitive items be transported without causing any damage to them. Construction and Heavy Tools Liftgates on flatbeds or heavy-duty trucks assist in securely moving tools, generators, and machinery to job sites.

Food and drink distribution. Quick loading and unloading of food under cold-chain logistics helps to maintain safe temperatures. In this industry, lift gates meant for speed and hygiene are vital.

Moving and Storage Companies

Advanced liftgates handle bulk items and furniture with reduced risk of damage. Operators can manage the lift from multiple angles using remote devices.

The Environmental Impact of New Liftgate Technology

Environmental responsibility is now a key consideration in logistics. Modern liftgates support green initiatives by:

Using electric power instead of hydraulic fluid reduces leaks and spills. Improving fuel economy through lighter builds. Reducing engine idling time with faster lift speeds.

Liftgate technology has advanced to improve safety and productivity.

Supporting EV integration

With compatible energy-efficient systems. This combination contributes to lower carbon footprints across fleets. Key Manufacturers Leading the Way Several companies have pioneered advanced liftgate technology, including:

Maxon Lift Corp.

Tommy Gate

Palfinger

Anthony Liftgates

Leyman Lift Gates

Final Thoughts

These brands offer customizable models with digital integration, safety upgrades, and energy-efficient systems to suit various commercial needs.

excellence in modern logistics. Through automation, digital integration, and eco-friendly designs, liftgates are helping companies become safer, faster, and more profitable.

As businesses strive for greater efficiency, lower costs, and reduced risks, upgrading to modern liftgate systems is not just an option—it’s a strategic necessity.

Conclusion

Manual labor and physical strain defined the cargo handling process; now, precision-engineered platforms, smart systems, and safety-first designs take center stage.

As we move into an increasingly connected and automated future, liftgates will continue to evolve, ensuring that safety and productivity rise together, load after load.

FQS

Q1. Do liftgates require special training to operate?

A: Yes. While many are user-friendly, training is essential to prevent misuse, ensure safety, and comply with occupational health standards.

Q2. How does telematics integration help fleet managers?

A: It provides real-time data on liftgate usage, wear and tear, and performance, helping managers schedule maintenance and optimize routes.

Q3. Are liftgates environmentally friendly?

A: Newer models often use battery power, lightweight materials, and efficient systems to reduce fuel consumption and environmental impact.

Q4. What industries benefit most from advanced liftgates?

A: Industries like e-commerce, retail, healthcare, food delivery, moving services, and construction all gain efficiency and safety from advanced liftgates.

Q5. Are there government regulations for liftgate safety?

A: Yes. In many countries, OSHA and DOT regulations apply. Manufacturers often design liftgates to meet or exceed these safety standards.

Leave a Reply